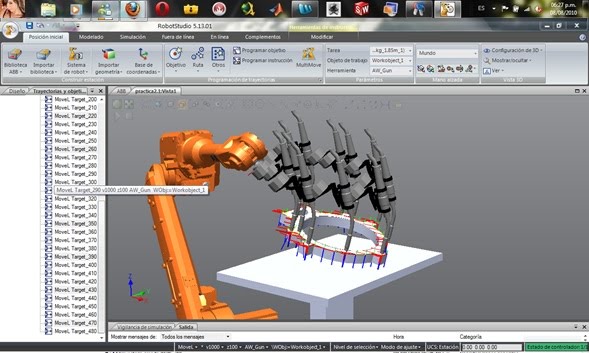

Operating manual RobotStudio 5.The IRB 1300 offers class-leading lifting ability, reach and path accuracy, in a faster, more compact package to enhance both productivity and production-line flexibility. The information in this manual is subject to change without notice and should not be construed as a commitment by ABB. ABB assumes no responsibility for any errors that may appear in this manual. wztemporary - Temporary world zone data.321 zonedata - Zone data.323. Except as may be expressly stated anywhere in this manual, nothing herein shall be construed as any kind of guarantee or warranty by ABB for losses, damages to persons or property, fitness for a specific purpose or the like. Abs Function RAPID reference part 2, Functions and data types A-Z 1 Abs - Gets the absolute value Abs is used to get the absolute value, i.e. In no event shall ABB be liable for incidental or consequential damages arising from use of this manual and products described herein. Proceedings of the International Conference on Automation Innovation in. This manual and parts thereof must not be reproduced or copied without ABB's written permission. For doing so, the team used one bridge where two ABB robotic arms were mounted. #Robotstudio world zones manualĪdditional copies of this manual may be obtained from ABB. The original language for this publication is English.

ABB AB Robotics Products SE-721 68 Västerås Sweden Any other languages that are supplied have been translated from English. 1.2.8 Libraries, geometries and CAD files. Conveyor tracking station with two robots. 2.2.1 Two robot systems in same task frame position. The new RobotStudio function uses ABB's superior motion control technology to predict the robot's movements with millimetric precision. 2.2.2 Two robot systems in different task frame positions. This allows the exact movement of the robot to be simulated in RobotStudio, enabling the user to determine the correct size of the safety zone required, and the ideal location of features including light curtains, safety fencing and controllers. Creating a system with external axes automatically. Manually setting up system with track motion. 2.4.1 Track motion of type RTT or IRBTx003.

2.6.3 Troubleshooting and optimizing geometries. 2.7.4 Setting the local origin of an object.

0 kommentar(er)

0 kommentar(er)